Most gun owners live with small problems longer than they should. A spring starts to feel a little soft. An extractor slips occasionally. A gun runs fine as long as everything lines up just right. Nothing breaks badly enough to force action, so owners ignore it. The gun still works, until it does not. When the failure finally shows up, it usually happens at the worst time. You now, at the range, during a class or, worse, when you need the gun the most.

These are not sudden failures. They are delayed ones.

When winter stopped feeling like downtime

For a long time, winter did not change that for me. I treated it like a pause. Fewer range trips meant less urgency, and guns stayed in the safe longer than they should have. I planned maintenance for later, much later, and told myself I would get to it when things warmed up.

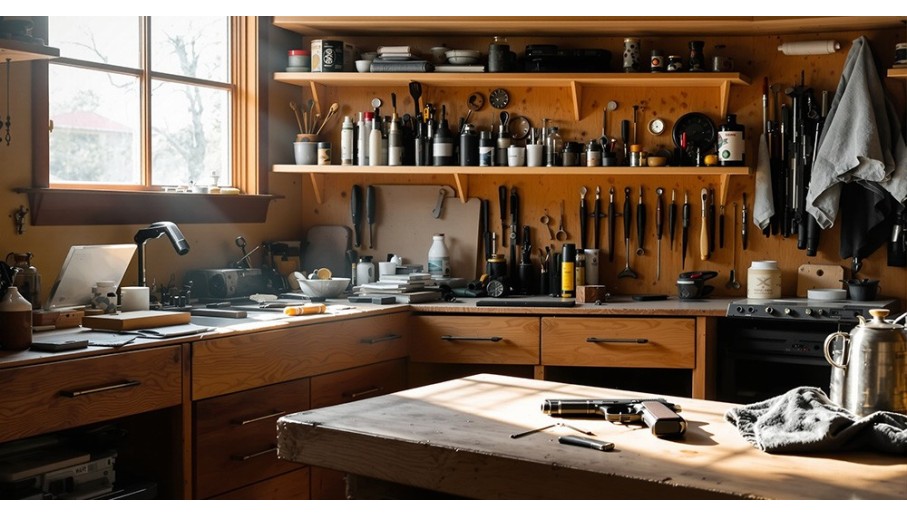

Right now, my old competition AR sits on the bench. I am working through every tight area, scraping carbon, cleaning out old lubricant, and replacing parts that show wear. This rifle sat in the back of a safe for a long time. Now it is preparing to go back to work, this time for product testing. The problems never went away. They waited.

The first time a gun failed during a spring range trip happened because of something I could have caught months earlier, the cost was clear. I lost time. I felt frustrated. I lost confidence in a gun that should have been reliable. That experience is why this AR sits on the bench now. That is why winter stopped feeling like downtime.

How slowing down changed what I noticed

During the busy months, maintenance moves fast. Clean it enough, lubricate it and put it back together. The goal is to shoot, not to inspect. Winter changes that balance.

With fewer trips planned, I do not rush reassembly. Guns stay apart longer, and I lay parts out instead of dropping them back into place. When the pace slows, problems surface. Springs feel weaker than they should. Pins show early wear marks. Extractors lose their edge but have not failed yet. None of these issues stop a gun from working immediately, but all of them warn of future failure.

Conflicts that keep problems alive

Over time, three conflicts became obvious. Time competes with attention. Convenience competes with reliability. Confidence competes with reality. A gun that ran last season feels trustworthy, but wear does not care about past performance. Quick cleaning feels productive. Inspection feels slow.

Ask yourself this question. Is that gun more or less trustworthy now than it was twelve months ago? Winter gives attention the upper hand. Do not ignore it.

Why winter exposes issues faster

Modern firearms leave little margin for error. Tighter tolerances and lighter components cause worn parts to show up sooner. Cold weather does not create problems. It exposes them.

Old lubricant no longer hides friction once temperatures drop, and marginal parts stop pretending they are fine. Winter makes these issues harder to ignore if you are willing to look.

Why preparation matters more than cleaning

Finding a worn part only helps if you can act on it. Here in Montana, a broken part can easily cost a week of downtime while you wait for a replacement to ship. That wait kills momentum. Projects stall, and owners put guns back into storage unfinished.

Winter maintenance works best when common wear parts are already on hand. Springs, pins and extractors wear quietly and fail without drama. Having them ready keeps winter work productive instead of frustrating.

There is no shortcut here

No spray fixes this. No lubricant repairs wear. No shortcut replaces inspection. No magic solution exists.

Winter maintenance works because it stays slow and deliberate. Guns come apart. Parts get laid out. Gun owners replace questionable components before they cause trouble.

What winter maintenance actually buys you

Guns maintained in winter run best when spring arrives. They run well not because of anything special, but because gun owners handled problems early, work happened without pressure and wear never reached failure.

That is the real value of winter on the bench.

Winter is also a practical time to stock the parts you know will wear. Whether you maintain a gun that needs attention or bring an old one back into service, winter work pays dividends when shooting season returns.

Now is a perfect time to stock up on parts! Pick up an EGP kit today and do your winter maintenance.

If you want to learn more about DIY Gunsmithing, check out my website at www.trb.fyi.

Author Bio

Jason Schaller has over 40 years of shooting experience and spent a decade as a licensed FFL gunsmith. Long before “DIY gunsmithing” was a buzzword, he was fixing and rebuilding firearms on his own bench. Today, he runs The Rogue Banshee, where he shares step-by-step guides that help everyday gun owners keep their firearms running and build confidence in their own skills. Visit him at www.trb.fyi, or on social networks like: